Onion and Garlic Processing in India Market

Romiter Machinery has many customer for onion processing in India. India onion price and garlic price is very low, which has very big export quantity. India also provide a large quantity dehydrated onion slice and garlic slice for global market. Now Romiter Onion Processing Machine is very popular in india, include onion peeling machien, onion root cutting machine, onion slicing machine, onion drying oven etc. We make some research on Onion and Garlic Market in inda, Here is the introduction.

Table of Contents

I. Introduction of Onions and Garlic in India

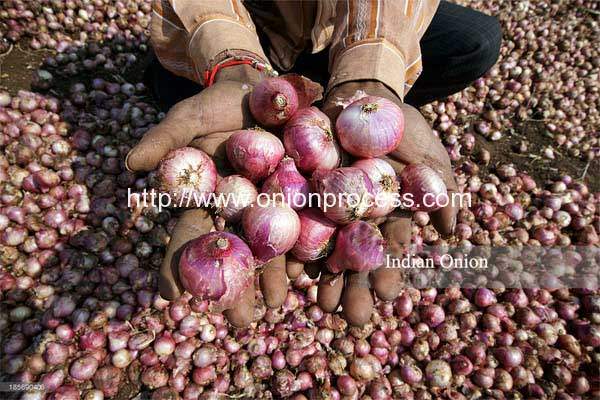

1. Indian Onions

India is the second largest onion producing country in the world, which has exported 1238,102.60 MT of fresh onions to the world for the worth of Rs. 2,300.57 crores during the year 2014-15. Major onion growing areas in India are Maharashtra, Karnataka, Madhya Pradesh, Gujarat, Bihar, Andhra Pradesh, Rajasthan, Haryana and Tamil Nadu. And Maharashtra with 27.72% onion production ranks first during these onion areas.

Indian onions are various in colors: Agrifound Dark Red, Agrifound Light Red, NHRDF Red, Agrifound White, Agrifound Rose and Agrifound Red, Pusa Ratnar, Pusa Red, Pusa White Round. Indian onion has two harvesting periods: the first period from November to January and the second period from January to May.

2. Indian Garlic

Garlic is the second important bulb crops grown after onion. Indian garlic production in world is very huge quantity and it generally ranks the second following China. The main garlic producing areas in India are Madhya Pradesh, Gujarat, Rajasthan, Uttar Pradesh. These four areas can respectively produce garlic of above 200,000 Mt. The garlic bulbs are generally white and big in size-about 4.5-5.0cm in diameter. Average yield is about 17-18 tonnes from a hectare. Indian garlic is well-known for its aroma with sweetness.

II. Market for Onion and Garlic Processing

1. Onion processing market

There is a huge demand for Indian onion in the world. Indian onions are mostly exported in the form of dehydrated onion, canned onion and onion pickle. Onions in India are processed into different forms of products: onion paste, dehydrated onion flakes, onion powder, onion oil, onion vinegar, onion sauce, pickled onion, onion wine and beverage etc. By rough estimate, around 6.75% of onion produced is going for processing. There is increasing demand for onion processed products due to its convenience to handle and use for customers and added onion values for manufacturers.

2. Garlic processing market

Garlic is one of the important bulb crops. It is used as a vegetable or condiment like pickle as important ingredient vinegar through India. Moreover, garlic is useful in various food products and herbal products. Garlic is often processed into these products like garlic powder, garlic salt, garlic vinegar, garlic oil, garlic juice and so on. Most of countries use these processed products in their food preparations like chutneys, pickles, curry powders, curried vegetables, meat and meat product preparations, tomato ketchup, etc.. And garlic processed products also have been extensively used as a popular remedy for various ailments and psychological disorders.

III. Onion Products Processing

1. Onion paste

Onion paste is one of the common ingredients required in preparing gravy for most of the Indian style paneer curries. Major production steps are as follows:

Fresh onions-onion peeling-onion root cutting-onion rinsing-onion slicing/shredding-onion crushing-onion milling-onion acidifying and heating-onion enzymolysis-onion beating-secondary milling-secondary heating-onion concentrating-onion paste canning-sealing-sterilizing-cooling-finished product

2. Dehydrated onion flake

● Slicing and washing

Use onion root cutting machine to cut onion tops and roots, then peel onions by peeling machine. Cut peeled onions with the thickness of 4-4.5mm by the slicing machine. Clean onion slices with water.

● Dewatering and drying

Remove the surface water of onions by the high speed rotation by the dewatering machine. Then lay these dewatered onion flakes on the drying plates with its hole diameter of 3*3mm or 5*5mm, and put drying plates on the drying vehicles. At last push into the drying oven for dehydration.

Thus, dehydrated onion flakes can be achieved.

Dehydration onions are featured with easy transportation and longer shelf life due to the bulk reduction and less moisture than fresh onions. By proper grinding, dehydrated onion flakes are easily processed into onion powder. Onion powder dissolves very easily and reconstitute quickly compared to onion flakes. So it is convenient to use onion powder to add the onion flavor for lots of foods.

3. Onion Oil

Onion oil is the flavoring substance which is widely used in the seasoning of processed products. Onion oil also can be regarded as the natural food preservative for certain food. The methods for processing onions into onion oil are as follows: distillation, solvent extraction, super critical fluid extraction and etc..

4. Onion pickles

Onion pickling methods approximately consist of venegar based pickling and oil based pickling. The former is favored in the United States and Europe and the later is utilized in Asia and Africa. Pickled onions are generally crisp and crunchy, and have a very sharp taste.

5. Onion beverage/sauce:

onions are rich in sugars and other nutrients, so they can be processed into onion wine, onion beverage and onion sauce.

IV. Garlic Products Processing Equipment

Garlic is often processed into garlic powder, garlic salt, garlic vinegar, garlic oil, garlic juice and so on. Before processing, garlic should be broken to separate the cloves. Garlic powder is made after flaking, drying and grinding the cloves. For making paste wet cloves are pilled and grind. The main garlic processing machines in the industrial production are: garlic grader, garlic separating machine, garlic peeling machine, garlic slicing machine, garlic paste making machine and so on.

V. Conclusion

Onion and garlic processed products are usually treated as the important ingredient of Indian cooking. It helps in absorption and digestion of food. In domestic market, processed and value added products are gaining importance in the household’s restaurants, eateries, caterers, and clubs use them regularly. With the medical property, these products have wide application in medicine. In the world market, the demand for onion and garlic products is increasing as they are hygiene and easy to handle, able to avoid wastage. There are good prospects for these processed products to export to gulf countries and even Europe.

Company Profile

Adhering to the principle of managing scientifically and honesty and credit,our factory has passed ISO9001-2000 quality system certification. Now, Our factory can provide onion dry cleaning machine, onion water washing machine, onion mesh bag packing machine, onion peeling machine, onion grader machine, onion root cutting machine, onion cutting machine, onion dryer machine, onion powder production line, onion powder bottle filling sealing machine.

Our onion processing products have passed with CE,ISO and SGS Certificates and has been widely sold all over the world.